Contract Manufacturing

At Synerxia we value ourselves as a differentiated, value-added, manufacturing and development partner: assisting performance Supplements with Dietary Health and wellness brands to rise to the next level with our high-quality dietary supplements.

We Are Serving

We are specialized in serving different forms of Supplements like Tablets, Effervescent Tablets, Vegan Capsules, Powders etc.

Our Product Range

Cardio Care

UTI & Women's Health

Anaemia & Malnourishment

Men Care

Menopuase & PCOS

Skin Care

Cognitive & Mental Health

Liver & Kidney Health

Bone & Jointcare

Children's Health

Eye Care

Immunity & General Wellness

Gut & Digestive Health

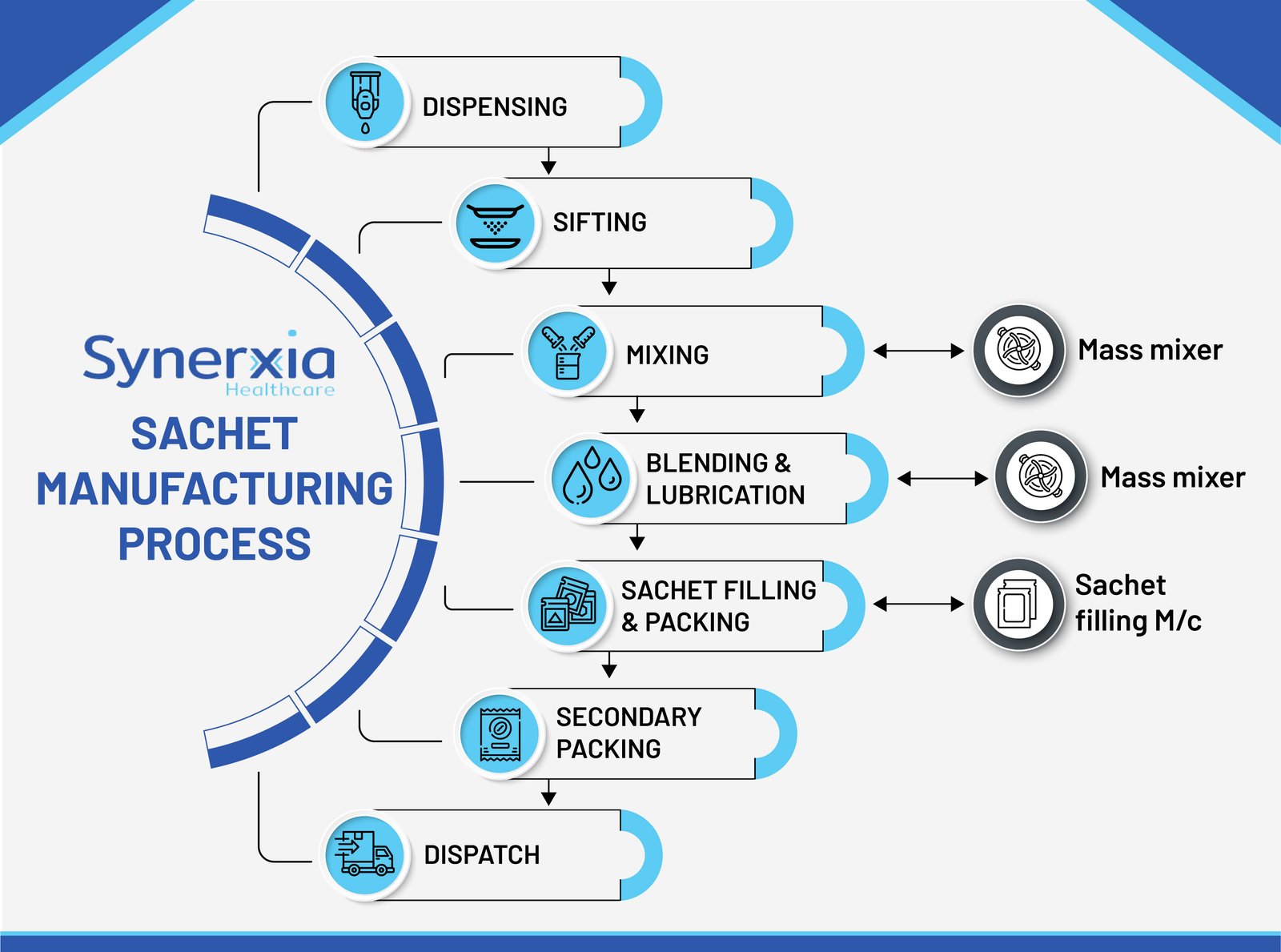

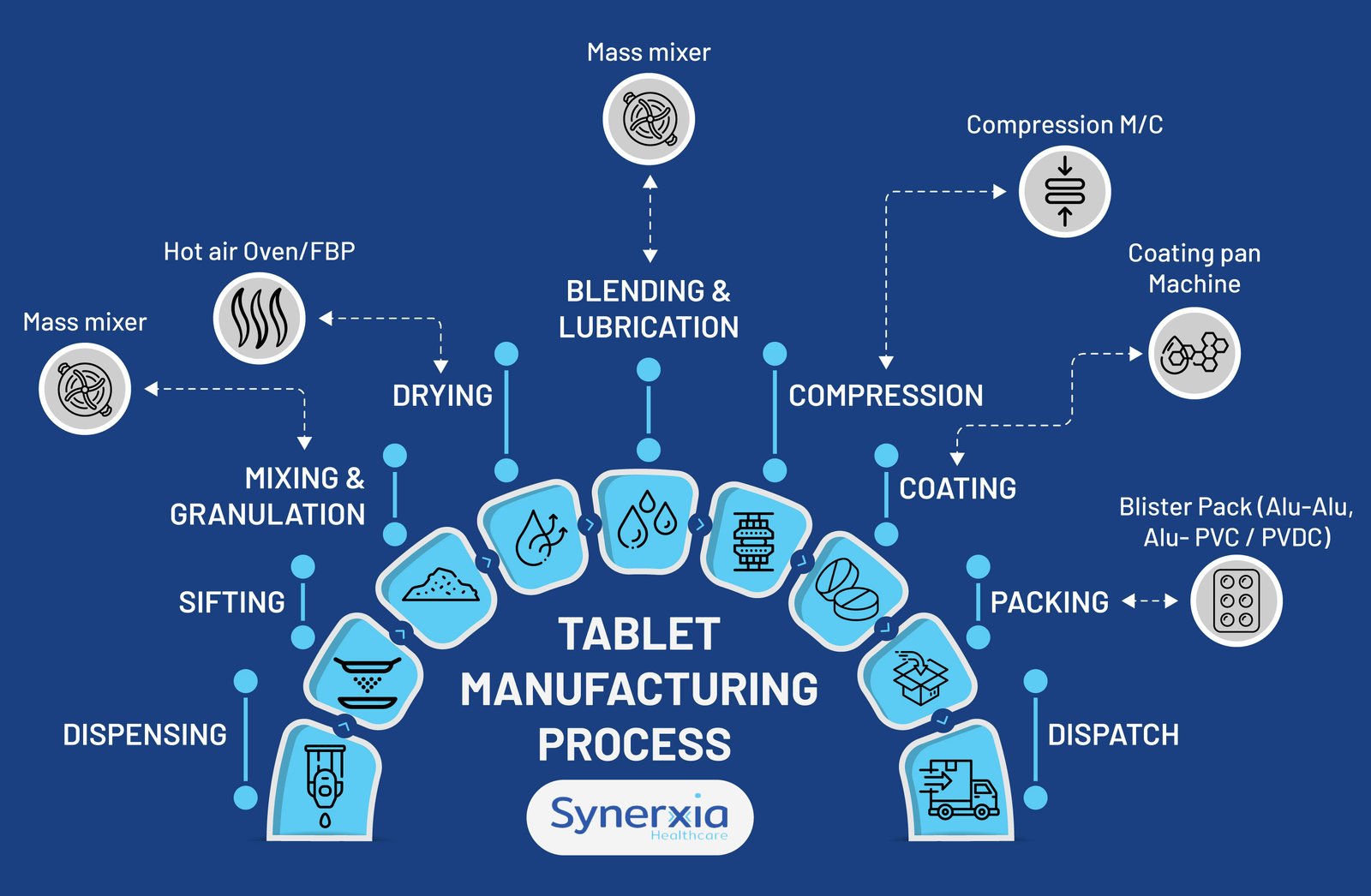

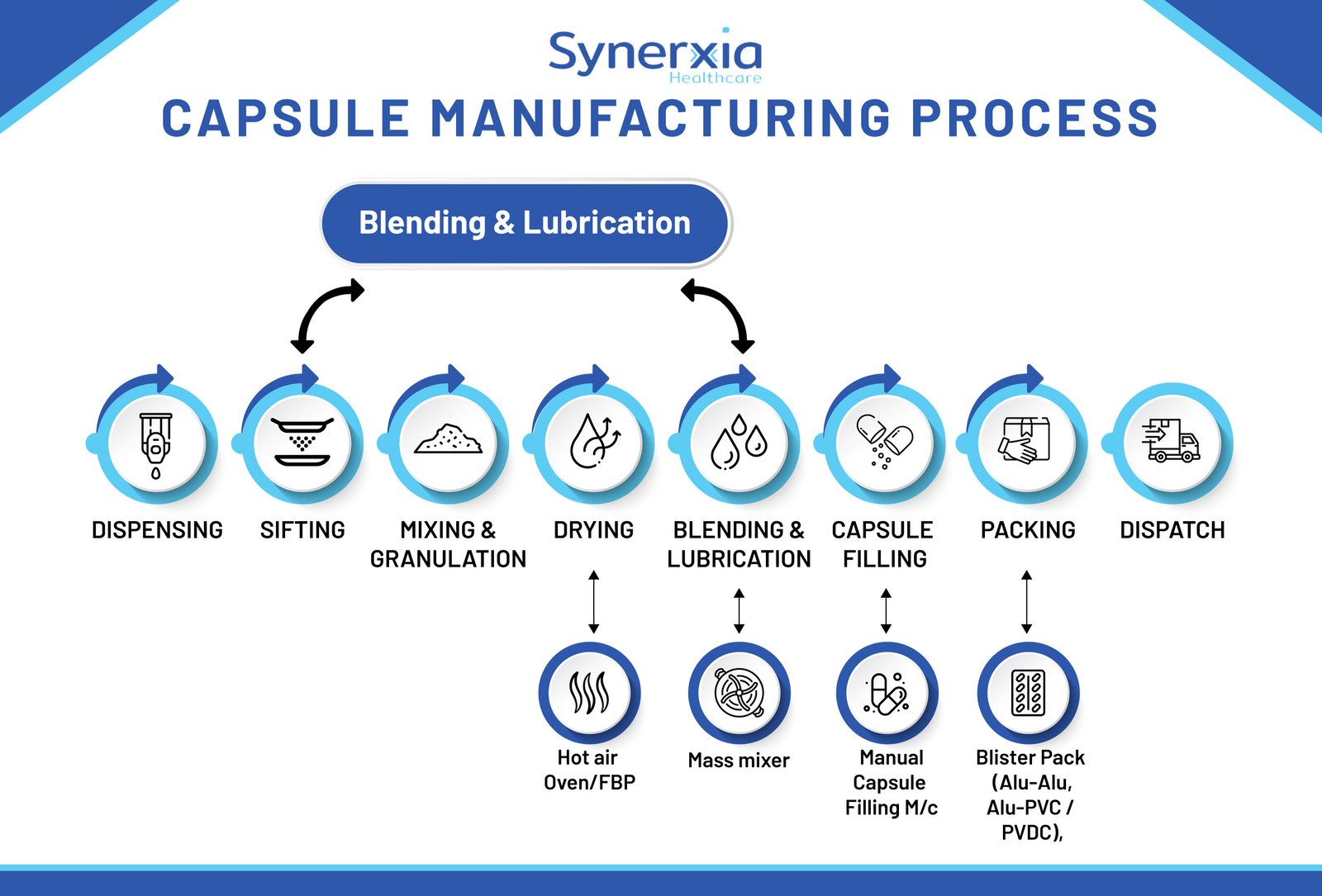

Our Contract Manufacturing Process

1. Dispensing

The precise measurement of raw materials based on the formula requirements. This ensures consistency and accuracy right from the start.

2. Sifting

Raw materials are sieved to remove impurities and ensure a uniform particle size for better mixing and flow.

3. Mixing & Granulation

The granules are dried using equipment like a Hot Air Oven or Fluidized Bed Processor (FBP) to remove excess moisture, achieving the required consistency.

4. Drying

The granules are dried using equipment like a Hot Air Oven or Fluidized Bed Processor (FBP) to remove excess moisture, achieving the required consistency.

5. Blending & Lubrication

The dried granules are mixed again, often with lubricants, to prepare for the final stage. This ensures smooth processing during compression or filling.

6. Filling

- Capsules: Filled using manual or automated capsule filling machines.

- Tablets: Compressed into solid forms using compression machines.

- Sachets: Filled with pre-measured doses using sachet-filling machines.

7. Coating (Optional for Tablets)

A protective layer is applied using a coating pan machine. This improves tablet stability and makes them easier to swallow.

8. Packing

The final product is packaged:

- Capsules & Tablets: Sealed in blister packs (Alu-Alu, Alu-PVC, or PVDC).

- Sachets: Placed in protective secondary packaging.

9. Dispatch

Completed products undergo quality checks and are dispatched for distribution.

Why Partner with Synerxia

Partnering with Synerxia ensures holistic quality, At every step, we take ownership of the entire product development process.

Meticulous sourcing to seamless manufacturing

Our Ethical conduct propels us forward

We evolve with science out of every single portfolio

We are offering elixirs of possibilities with different portfolios of the products

Frequently Asked Questions

Private label manufacturing involves creating products for other companies to sell under their own brand.

Yes, We as a manufacturer offer customization options.

We comply with stringent regulations following FSSAI, cGMP, FDA, ISO, HALAL & KOSHER to maintain quality standards to ensure product safety and efficacy.

We have FSSAI, cGMP, HALAL, ISO 9000-22000, KOSHER & other Approvals.

We offer Tablets, Vegan Capsules, Effervescents, Sachets, Powders.

Yes we do comply with International regulations, and it’s a reason we are available in the Global market following stringent Regulatory Compliance.

Phone

+91-7202004009

info@synerxia.com

Office Address

404-Sangam Sapphire, Science City Road, Sola, Ahmedabad - 380060, Gujarat, India

Manufacturing Address

J-27, Orchid Industrial Park, Near Police HeadQuarters, Sanand-Bavla Road, Bavla, Dist Ahmedabd, Gujarat-382220